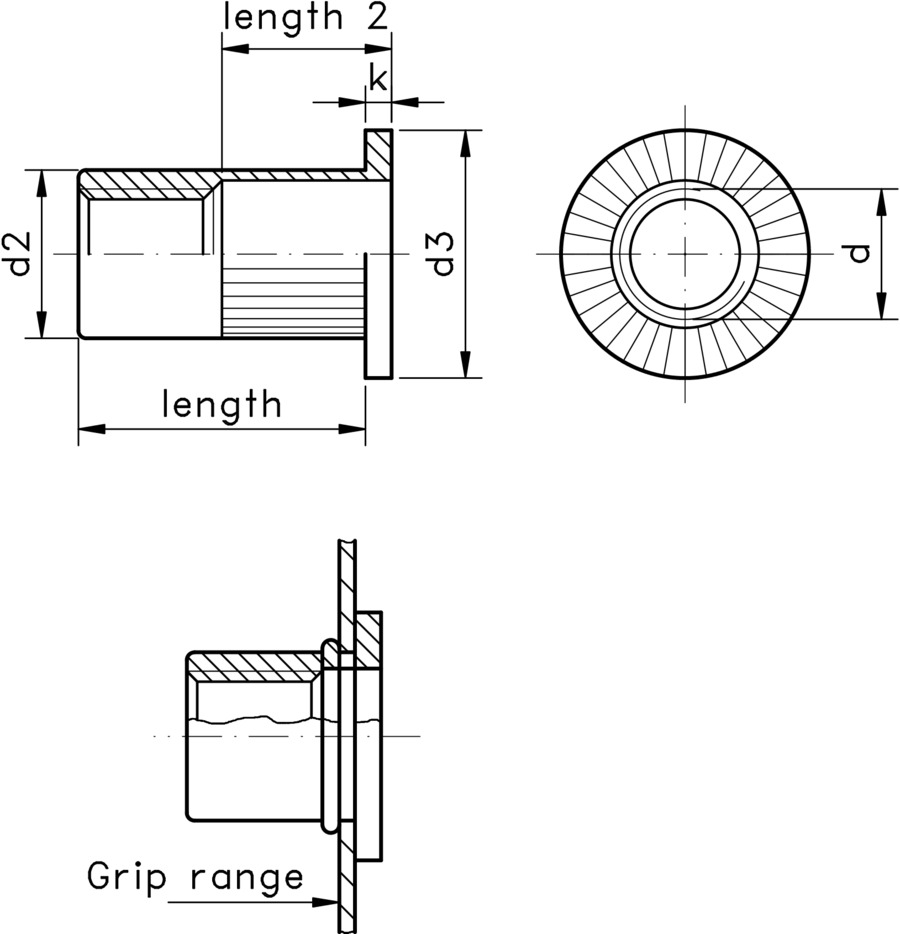

Rivet Nuts - Flat Head with Knurled Shank, Open Type

This product guide contains the specification for blind rivet nuts with a flat head, a straight knurled shank and an open end, a stock item available from Westfield Fasteners.

Blind rivet nuts are installed by inserting the rivet nut into the correctly sized and shaped hole within the sheet material. The rivet nut is compressed using a pneumatic powered or hand rivet nut tool, gripping it firmly to the sheet material.

In the compression process, the thinner walled section without the thread collapses to form a collar on the blind side of the sheet material. This prevents the nut from being pulled back though the hole and fixes it securely to the sheet material.

Like blind rivets, rivet nuts do not require access to the back of the material. Features like knurling or the hexagonal shaped body within a hexagonal shaped hole will help prevent the rivet nut from turning.

This particular type of rivet nut features a flat top, a straight knurled body and open end, and is a more common type of rivet nut. The larger diameter of the flat head will spread the load over a greater surface area, making them appropriate for most applications, including connecting soft or brittle materials to a rigid backing.

The knurling/serrations will help to grip the nut to the connecting materials and stop it turning. The open end allows a bolt of any length to be used with the rivet nut, making it more vibration resistant.

This type of rivet nut is used in a multitude of industries such as aerospace, automotive, rail, HVAC, white goods, electronics, DIY and general engineering.

These Rivet Nuts are produced in A2 and A4 Stainless Steel, zinc plated steel, and aluminium.