Westfield Fasteners Product Specification:

DIN 7 - Dowel Pin / Parallel Pin

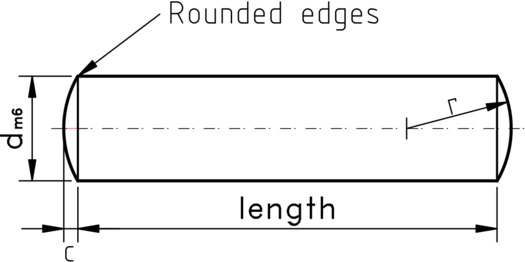

This product guide contains the specification for metric sized parallel pins or dowel pins, a series of standard parts available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 7, specifically the variant with an m6 fit.

Dowel Pins or Parallel Pins are short cylindrical sections of metal used for precise alignment of machine parts and mould tools. They are often also used as reference points for mechanical engineers to ensure repeatable and accurate assemblies. The diameter of these parts is produced to a specific tolerance so that the desired fit can be acheived with a suitably sized and toleranced hole. In this case the ISO fit code is m6.

Scope of the DIN standard.

DIN 7 defines the form, and specifies the dimensions and tolerances for these dowel pins, for sizes incremental from 1mm up to and including 50mm diameter. The DIN standard includes information on a number of parallel pin designs featuring fits other than m6.

Figure 1 below illustrates the basic design, and should be used with table 1 for tolerance information on the end treatment, and table 2 for tolerances on the length as illustrated. The information in table 3 shows the tolerances on a shaft with an m6 fit, in sizes relevant to these parallel or dowel pins. This information is taken from the standard ISO 286.