DIN 472 - Internal Circlip

This product guide contains the specification for internal circlips to the standard DIN 472. These circlips are standard parts available from Westfield Fasteners.

Internal circlips/retaining rings are used to secure components or assemblies, such as bearings, in bore holes and to help transfer axial forces.

Made from a spring or stainless steel, retaining rings are assembled using pliers conforming to DIN 5256, or can be located with a taper.

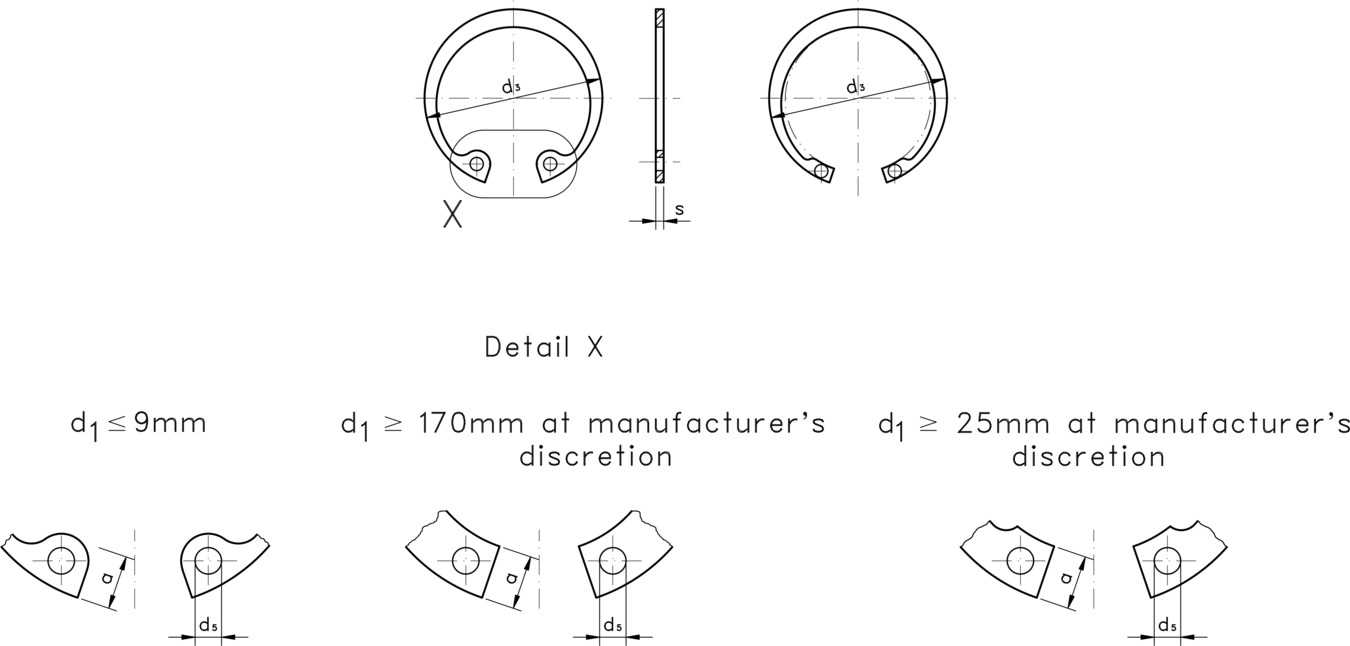

Figure 1: Internal Circlip, General Layout

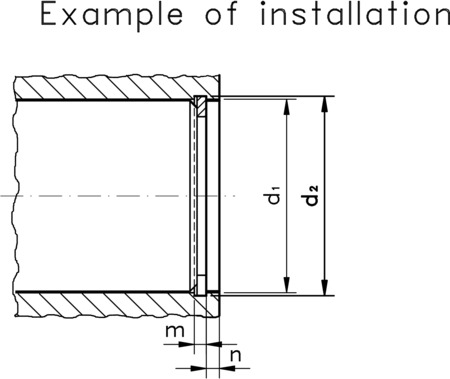

Figure 2: Internal Circlip, Sectional View of Fitment

| Shaft Diameter | Ring | Groove | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1 | S | d3 | a | b | d5 | Mass per 1000 unit in kg | d2 | m | t | n4 | |||

| Nom | - | perm. dev. | - | perm. dev. | max | = | min | = | - | per. dev. | H13 | - | min |

| 8 | 0.80 | 0/-0.05 | 8.7 | +0.36/-0.10 | 2.4 | 1.1 | 1.0 | 0.14 | 8.4 | +0.09/0 | 0.90 | 0.20 | 0.6 |

| 9 | 0.80 | 9.8 | 2.5 | 1.3 | 1.0 | 0.15 | 9.4 | 0.90 | 0.20 | 0.6 | |||

| 10 | 1.00 | 0/-0.06 | 10.8 | 3.2 | 1.4 | 1.2 | 0.18 | 10.4 | +0.11/0 | 1.10 | 0.20 | 0.6 | |

| 11 | 1.00 | 11.8 | 3.3 | 1.5 | 1.2 | 0.31 | 11.4 | 1.10 | 0.20 | 0.6 | |||

| 12 | 1.00 | 13.0 | 3.4 | 1.7 | 1.5 | 0.37 | 12.5 | 1.10 | 0.25 | 0.8 | |||

| 13 | 1.00 | 14.1 | 3.6 | 1.8 | 1.5 | 0.42 | 13.6 | 1.10 | 0.30 | 0.9 | |||

| 14 | 1.00 | 15.1 | 3.7 | 1.9 | 1.7 | 0.52 | 14.6 | 1.10 | 0.30 | 0.9 | |||

| 15 | 1.00 | 16.2 | 3.7 | 2.0 | 1.7 | 0.56 | 15.7 | 1.10 | 0.35 | 1.1 | |||

| 16 | 1.00 | 17.3 | 3.8 | 2.0 | 1.7 | 0.60 | 16.8 | 1.10 | 0.40 | 1.2 | |||

| 17 | 1.00 | 18.3 | +0.42/-0.13 | 3.9 | 2.1 | 1.7 | 0.65 | 17.8 | 1.10 | 0.40 | 1.2 | ||

| 18 | 1.00 | 19.5 | 4.1 | 2.2 | 2.0 | 0.74 | 19.0 | +0.13/0 | 1.10 | 0.50 | 1.5 | ||

| 19 | 1.00 | 20.5 | 4.1 | 2.2 | 2.0 | 0.86 | 20.0 | 1.10 | 0.50 | 1.5 | |||

| 20 | 1.00 | 21.5 | 4.2 | 2.3 | 2.0 | 0.90 | 21.0 | 1.10 | 0.50 | 1.5 | |||

| 21 | 1.00 | 22.5 | 4.2 | 2.4 | 2.0 | 1.00 | 22.0 | 1.10 | 0.50 | 1.5 | |||

| 22 | 1.00 | 23.5 | 4.2 | 2.5 | 2.0 | 1.10 | 23.0 | 1.10 | 0.50 | 1.5 | |||

| 23 | - | - | - | - | - | - | - | - | - | - | - | - | |

| 24 | 1.20 | 25.9 | +0.42/-0.13 | 4.4 | 2.6 | 2.0 | 1.42 | 25.2 | +0.21/0 | 1.30 | 0.60 | 1.8 | |

| 25 | 1.20 | 26.9 | 4.5 | 2.7 | 2.0 | 1.50 | 26.2 | 1.30 | 0.60 | 1.8 | |||

| 26 | 1.20 | 27.9 | 4.7 | 2.8 | 2.0 | 1.60 | 27.2 | 1.30 | 0.60 | 1.8 | |||

| 27 | - | - | - | - | - | - | - | - | - | - | - | ||

| 28 | 1.20 | 30.1 | +0.50/-0.25 | 4.8 | 2.9 | 2.0 | 1.80 | 29.4 | 1.30 | 0.70 | 2.1 | ||

| 29 | - | - | - | - | - | - | - | - | - | - | - | ||

| 30 | 1.20 | 32.1 | 4.8 | 3.0 | 2.0 | 2.06 | 31.4 | +0.25/0 | 1.30 | 0.70 | 2.1 | ||

| 31 | 1.50 | 33.4 | 5.2 | 3.2 | 2.5 | 2.10 | 32.7 | 1.30 | 0.85 | 2.6 | |||

| 32 | 1.50 | 34.4 | 5.4 | 3.2 | 2.5 | 2.21 | 33.7 | 1.30 | 0.85 | 2.6 | |||

| 33 | - | - | - | - | - | - | - | 1.060 | - | - | |||

| 34 | 1.50 | 36.5 | 5.4 | 3.3 | 2.5 | 3.20 | 35.7 | 1.60 | 0.85 | 2.6 | |||

| 35 | 1.50 | 37.8 | 5.4 | 3.4 | 2.5 | 3.54 | 37.0 | 1.60 | 1.00 | 3.0 | |||

| Shaft Diameter | Ring | Groove | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1 | S | d3 | a | b | d5 | Mass per 1000 unit in kg | d2 | m | t | n4 | |||

| Nom | - | perm. dev. | - | perm. dev. | max | = | min | = | - | per. dev. | H13 | - | min |

| 36 | 1.50 | 0/-0.06 | 38.8 | +0.50/-0.25 | 5.4 | 3.5 | 2.5 | 3.70 | 38.0 | +0.25/0 | 1.60 | 1.00 | 3.0 |

| 37 | 1.50 | 39.8 | 5.5 | 3.6 | 2.5 | 3.74 | 39.0 | 1.60 | 1.00 | 3.0 | |||

| 38 | 1.50 | 40.8 | 5.5 | 3.7 | 2.5 | 3.90 | 40.0 | 1.60 | 1.00 | 3.0 | |||

| 39 | - | - | - | - | - | - | - | - | - | - | - | ||

| 40 | 1.75 | 43.5 | +0.90/-0.39 | 5.8 | 3.9 | 2.5 | 4.70 | 42.5 | 1.85 | 1.25 | 3.8 | ||

| 41 | - | - | - | - | - | - | - | - | - | - | |||

| 42 | 1.75 | 45.5 | 5.9 | 4.1 | 2.5 | 5.40 | 44.5 | 1.85 | 1.25 | 3.8 | |||

| 43 | - | - | - | - | - | - | - | - | - | - | |||

| 44 | - | - | - | - | - | - | - | - | - | - | |||

| 45 | 1.75 | 48.5 | 6.2 | 4.3 | 2.5 | 6.00 | 47.5 | 1.85 | 1.25 | 3.8 | |||

| 47 | 1.75 | 50.5 | +1.10/-0.46 | 6.4 | 4.4 | 2.5 | 6.10 | 49.5 | 1.85 | 1.25 | 3.8 | ||

| 48 | 1.75 | 51.5 | 6.4 | 4.5 | 2.5 | 6.70 | 50.5 | +0.30/0 | 1.85 | 1.25 | 3.8 | ||

| 50 | 2.00 | 0/-0.07 | 54.2 | 6.5 | 4.6 | 2.5 | 7.30 | 53.0 | 2.15 | 1.50 | 4.5 | ||

| 52 | 2.00 | 56.2 | 6.7 | 4.7 | 2.5 | 8.20 | 55.0 | 2.15 | 1.50 | 4.5 | |||

| 54 | - | - | - | - | - | - | - | 2.15 | 1.50 | 4.5 | |||

| 55 | 2.00 | 59.2 | 6.8 | 5.0 | 2.5 | 8.30 | 58.0 | 2.15 | 1.50 | 4.5 | |||

| 56 | 2.00 | 60.2 | 6.8 | 5.1 | 2.5 | 8.70 | 59.0 | 2.15 | 1.50 | 4.5 | |||

| 58 | 2.00 | 62.2 | 6.9 | 5.2 | 2.5 | 10.50 | 61.0 | 2.15 | 1.50 | 4.5 | |||

| 60 | 2.00 | 64.2 | 7.3 | 5.4 | 2.5 | 11.10 | 63.0 | 2.15 | 1.50 | 4.5 | |||

| 62 | 2.00 | 66.2 | 7.3 | 5.5 | 2.5 | 11.20 | 65.0 | 2.15 | 1.50 | 4.5 | |||

| 63 | 2.00 | 67.2 | 7.3 | 5.6 | 2.5 | 12.40 | 66.0 | 2.15 | 1.50 | 4.5 | |||

| 65 | 2.50 | 69.2 | 7.6 | 5.8 | 3.0 | 14.30 | 68.0 | 2.65 | 1.50 | 4.5 | |||

| 68 | 2.50 | 72.5 | 7.8 | 6.1 | 3.0 | 16.00 | 71.0 | 2.65 | 1.50 | 4.5 | |||

| 70 | 2.50 | 74.5 | 7.8 | 6.2 | 3.0 | 16.50 | 73.0 | 2.65 | 1.50 | 4.5 | |||

| 72 | 2.50 | 76.5 | 7.8 | 6.4 | 3.0 | 18.10 | 75.0 | 2.65 | 1.50 | 4.5 | |||

| 75 | 2.50 | 79.5 | 7.8 | 6.6 | 3.0 | 18.80 | 78.0 | 2.65 | 1.50 | 4.5 | |||

| 78 | 2.50 | 82.5 | +1.30/-0.54 | 8.5 | 6.8 | 3.0 | 20.40 | 81.0 | +0.35/0 | 2.65 | 1.50 | 4.5 | |

| 80 | 2.50 | 85.5 | 8.5 | 7.0 | 3.0 | 22.00 | 83.5 | 2.65 | 1.75 | 5.3 | |||

| 82 | 2.50 | 87.5 | 8.5 | 7.0 | 3.0 | 24.00 | 85.5 | 2.65 | 1.75 | 5.3 | |||

| 85 | 3.00 | 0/-0.08 | 90.5 | 8.6 | 7.2 | 3.5 | 25.30 | 88.5 | 3.15 | 1.75 | 5.3 | ||

| 88 | 3.00 | 93.5 | 8.6 | 7.4 | 3.5 | 28.00 | 91.5 | 3.15 | 1.75 | 5.3 | |||

| 90 | 3.00 | 95.5 | 8.6 | 7.6 | 3.5 | 31.00 | 93.5 | 3.15 | 1.75 | 5.3 | |||

| 92 | 3.00 | 97.5 | 8.7 | 7.8 | 3.5 | 32.00 | 95.5 | 3.15 | 1.75 | 5.3 | |||

| 95 | 3.00 | 100.5 | 8.8 | 8.1 | 3.5 | 35.00 | 98.5 | 3.15 | 1.75 | 5.3 | |||

| 98 | 3.00 | 103.5 | 9.0 | 8.3 | 3.5 | 37.00 | 101.5 | 3.15 | 1.75 | 5.3 | |||

| 100 | 3.00 | 105.5 | 9.2 | 8.4 | 3.5 | 38.00 | 103.5 | 3.15 | 1.75 | 5.3 | |||