DIN 471 - External Circlip

This product guide contains the specification for external circlips to the standard DIN 471. These circlips are standard parts available from Westfield Fasteners.

External circlips offer a strong grip and reduce the chance of slipping. They are often used in assemblies that are subject to strong centrifugal forces or high rotational speeds.

These external circlips/retaining rings for shafts are used to hold components or assemblies, such as bearings and other parts that will rotate around the shaft.

Made from a spring or stainless steel, retaining rings are assembled using pliers conforming to DIN 5254, or can be located using tapers.

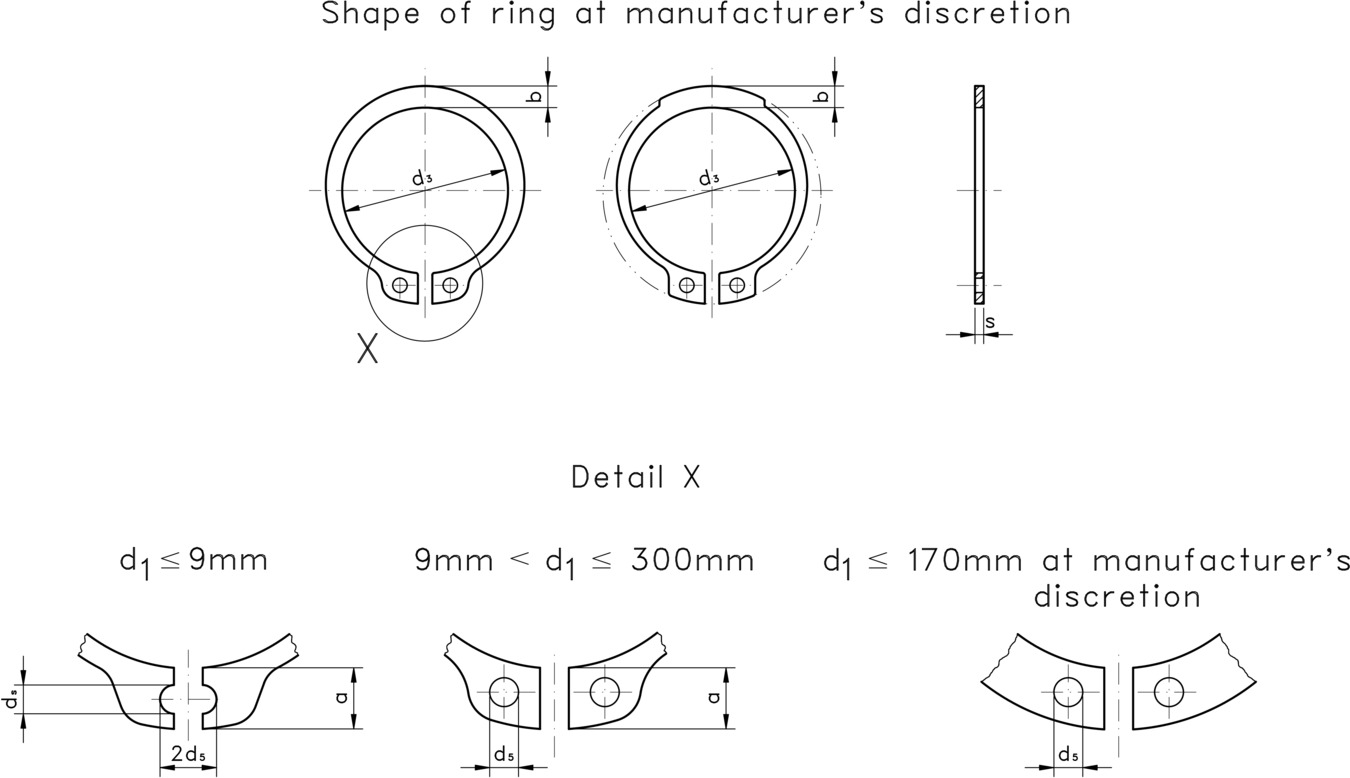

Figure 1: External Circlip, General Layout

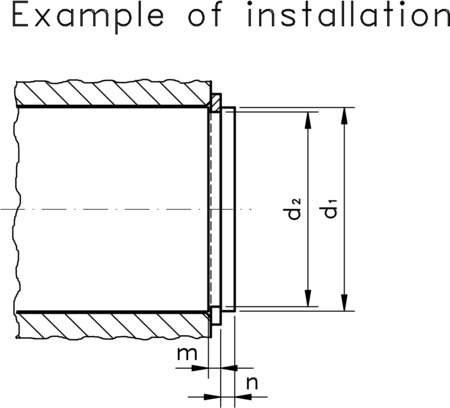

Figure 2: External Circlip, Sectional View of Fitment

| Shaft Diameter | Ring | Groove | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1 | S | d3 | a | b | d5 | Mass per 1000 unit in kg | d2 | m | t | n4 | |||

| Nom | - | perm. dev. | - | perm. dev. | max | = | min | = | - | per. dev. | H13 | - | min |

| 3 | 0.4 | 0/-0.05 | 2.7 | +0.04/-0.15 | 1.9 | 0.8 | 1.0 | 0.017 | 2.8 | 0/-0.04 | 0.5 | 0.10 | 0.3 |

| 4 | 0.4 | 3.7 | 2.2 | 0.9 | 1.0 | 0.022 | 3.8 | 0/-0.05 | 0.5 | 0.10 | 0.3 | ||

| 5 | 0.6 | 4.7 | 2.5 | 1.1 | 1.0 | 0.066 | 4.8 | 0.7 | 0.10 | 0.3 | |||

| 6 | 0.7 | 5.6 | 2.7 | 1.3 | 1.2 | 0.084 | 5.7 | 0.8 | 0.15 | 0.5 | |||

| 7 | 0.8 | 6.5 | +0.06/-0.18 | 3.1 | 1.4 | 1.2 | 0.121 | 6.7 | 0/-0.06 | 0.9 | 0.15 | 0.5 | |

| 8 | 0.8 | 7.4 | 3.2 | 1.5 | 1.2 | 0.158 | 7.6 | 0.9 | 0.20 | 0.6 | |||

| 9 | 1.0 | 0/-0.06 | 8.4 | 3.3 | 1.7 | 1.2 | 0.300 | 8.6 | 0/-0.11 | 1.1 | 0.20 | 0.6 | |

| 10 | 1.0 | 9.3 | +0.10/-0.36 | 3.3 | 1.8 | 1.5 | 0.340 | 9.6 | 1.1 | 0.20 | 0.6 | ||

| 11 | 1.0 | 10.2 | 3.3 | 1.8 | 1.5 | 0.410 | 10.5 | 1.1 | 0.25 | 0.8 | |||

| 12 | 1.0 | 11.0 | 3.3 | 1.8 | 1.7 | 0.500 | 11.5 | 1.1 | 0.25 | 0.8 | |||

| 13 | 1.0 | 11.9 | 3.4 | 2.0 | 1.7 | 0.530 | 12.4 | 1.1 | 0.30 | 0.9 | |||

| 14 | 1.0 | 12.9 | 3.5 | 2.1 | 1.7 | 0.640 | 13.4 | 1.1 | 0.30 | 0.9 | |||

| 15 | 1.0 | 13.8 | 3.6 | 2.2 | 1.7 | 0.670 | 14.3 | 1.1 | 0.35 | 1.1 | |||

| 16 | 1.0 | 14.7 | 3.7 | 2.2 | 1.7 | 0.700 | 15.2 | 1.1 | 0.40 | 1.2 | |||

| 17 | 1.0 | 15.7 | 3.8 | 2.3 | 1.7 | 0.820 | 16.2 | 1.1 | 0.40 | 1.2 | |||

| 18 | 1.20 | 16.5 | 3.9 | 2.4 | 2.0 | 1.110 | 17.0 | 1.30 | 0.50 | 1.5 | |||

| 19 | 1.20 | 17.5 | 3.9 | 2.5 | 2.0 | 1.220 | 18.0 | 1.30 | 0.50 | 1.5 | |||

| 20 | 1.20 | 18.5 | +0.13/-0.42 | 4.0 | 2.6 | 2.0 | 1.300 | 19.0 | 0/-0.13 | 1.30 | 0.50 | 1.5 | |

| 21 | 1.20 | 19.5 | 4.1 | 2.7 | 2.0 | 1.420 | 20.0 | 1.30 | 0.50 | 1.5 | |||

| 22 | 1.20 | 20.5 | 4.2 | 2.8 | 2.0 | 1.500 | 21.0 | 1.30 | 0.50 | 1.5 | |||

| 23 | - | - | - | - | - | - | - | - | - | - | - | - | |

| 24 | 1.20 | 22.2 | +0.21/-0.42 | 4.4 | 3.0 | 2.0 | 1.770 | 22.9 | 0/-0.21 | 1.30 | 0.55 | 1.7 | |

| 25 | 1.20 | 23.2 | 4.4 | 3.0 | 2.0 | 1.900 | 23.9 | 1.30 | 0.55 | 1.7 | |||

| 26 | 1.20 | 24.2 | 4.5 | 3.1 | 2.0 | 1.960 | 24.9 | 1.30 | 0.55 | 1.7 | |||

| 27 | - | - | - | - | - | - | - | - | - | - | |||

| 28 | 1.50 | 25.9 | 4.7 | 3.2 | 2.0 | 2.920 | 26.6 | 1.60 | 0.70 | 2.1 | |||

| 29 | 1.50 | 26.9 | 4.8 | 3.4 | 2.0 | 3.200 | 27.6 | 1.60 | 0.70 | 2.1 | |||

| 30 | 1.50 | 27.9 | 5.0 | 3.5 | 2.0 | 3.310 | 28.6 | 1.60 | 0.70 | 2.1 | |||

| Shaft Diameter | Ring | Groove | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1 | S | d3 | a | b | d5 | Mass per 1000 unit in kg | d2 | m | t | n | |||

| Nom | - | perm. dev. | - | perm. dev. | max | = | min | = | - | per. dev. | H13 | - | min |

| 30 | 1.50 | 0/-0.06 | 27.9 | +0.21/-0.42 | 5.0 | 3.5 | 2.0 | 3.31 | 28.6 | 0/-0.21 | 1.60 | 0.70 | 2.1 |

| 32 | 1.50 | 29.6 | 5.2 | 3.6 | 2.5 | 3.54 | 30.3 | 0/-0.25 | 1.60 | 0.85 | 2.6 | ||

| 34 | 1.50 | 31.5 | +0.25/-0.5 | 5.4 | 3.8 | 2.5 | 3.80 | 32.3 | 1.60 | 0.85 | 2.6 | ||

| 35 | 1.50 | 32.2 | 5.6 | 3.9 | 2.5 | 4.00 | 33.0 | 1.60 | 1.00 | 3.0 | |||

| 36 | 1.75 | 33.2 | 5.6 | 4.0 | 2.5 | 5.00 | 34.0 | 1.85 | 1.00 | 3.0 | |||

| 37 | - | - | - | - | - | - | - | - | - | - | |||

| 38 | 1.75 | 35.2 | 5.8 | 4.2 | 2.5 | 5.62 | 36.0 | 1.85 | 1.00 | 3.0 | |||

| 39 | - | - | - | - | - | - | - | - | - | - | - | ||

| 40 | 1.75 | 36.5 | +0.39/-0.9 | 6.0 | 4.4 | 2.5 | 6.03 | 37.5 | 1.85 | 1.25 | 3.8 | ||

| 42 | 1.75 | 38.5 | 6.5 | 4.5 | 2.5 | 6.50 | 39.5 | 1.85 | 1.25 | 3.8 | |||

| 44 | - | - | - | - | - | - | - | - | - | - | |||

| 45 | 1.75 | 41.5 | 6.7 | 4.7 | 2.5 | 7.50 | 42.5 | 1.85 | 1.25 | 3.8 | |||

| 46 | - | - | - | - | - | - | - | - | - | - | |||

| 47 | - | - | - | - | - | - | - | - | - | - | |||

| 48 | 1.75 | 44.5 | 6.9 | 5.0 | 2.5 | 7.90 | 45.5 | 1.85 | 1.25 | 3.8 | |||

| 50 | 2.0 | 0/-0.07 | 45.8 | 6.9 | 5.1 | 2.5 | 10.20 | 47.0 | 2.15 | 1.50 | 4.5 | ||

| 52 | 2.0 | 47.8 | 7.0 | 5.2 | 2.5 | 11.10 | 49.0 | 2.15 | 1.50 | 4.5 | |||

| 55 | 2.0 | 50.8 | +0.46/-1.1 | 7.2 | 5.4 | 2.5 | 11.40 | 52.0 | 0/-0.30 | 2.15 | 1.50 | 4.5 | |

| 56 | 2.0 | 51.5 | 7.3 | 5.5 | 2.5 | 11.80 | 53.0 | 2.15 | 1.50 | 4.5 | |||

| 58 | 2.0 | 53.5 | 7.3 | 5.6 | 2.5 | 12.60 | 55.0 | 2.15 | 1.50 | 4.5 | |||

| 60 | 2.0 | 55.8 | 7.4 | 5.8 | 2.5 | 12.90 | 57.0 | 2.15 | 1.50 | 4.5 | |||

| 62 | 2.0 | 57.8 | 7.5 | 6.0 | 2.5 | 14.30 | 59.0 | 2.15 | 1.50 | 4.5 | |||

| 63 | 2.0 | 58.8 | 7.6 | 6.2 | 2.5 | 15.90 | 60.0 | 2.15 | 1.50 | 4.5 | |||

| 65 | 2.5 | 60.8 | 7.8 | 6.3 | 3.0 | 18.20 | 62.0 | 2.65 | 1.50 | 4.5 | |||

| 68 | 2.5 | 63.5 | 8.0 | 6.5 | 3.0 | 21.80 | 65.0 | 2.65 | 1.50 | 4.5 | |||

| 70 | 2.5 | 65.5 | 8.1 | 6.6 | 3.0 | 22.00 | 67.0 | 2.65 | 1.50 | 4.5 | |||

| 72 | 2.5 | 67.5 | 8.2 | 6.8 | 3.0 | 22.50 | 69.0 | 2.65 | 1.50 | 4.5 | |||

| 75 | 2.5 | 70.5 | 8.4 | 7.0 | 3.0 | 24.60 | 72.0 | 2.65 | 1.50 | 4.5 | |||

| 78 | 2.5 | 73.5 | 8.6 | 7.3 | 3.0 | 26.20 | 75.0 | 2.65 | 1.50 | 4.5 | |||

| 80 | 2.5 | 74.5 | 8.6 | 7.4 | 3.0 | 27.30 | 76.5 | 2.65 | 1.75 | 5.3 | |||

| 82 | 2.5 | 76.5 | 8.7 | 7.6 | 3.0 | 31.20 | 78.5 | 2.65 | 1.75 | 5.3 | |||

| 85 | 3.0 | 0/-0.08 | 79.5 | 8.7 | 7.8 | 3.5 | 36.40 | 81.5 | 0/-0.54 | 3.15 | 1.75 | 5.3 | |

| 88 | 3.0 | 82.5 | +0.54/-1.3 | 8.8 | 8.0 | 3.5 | 41.20 | 84.5 | 3.15 | 1.75 | 5.3 | ||

| 90 | 3.0 | 84.5 | 8.8 | 8.2 | 3.5 | 44.50 | 86.5 | 3.15 | 1.75 | 5.3 | |||

| 95 | 3.0 | 89.5 | 9.4 | 8.6 | 3.5 | 49.00 | 91.5 | 3.15 | 1.75 | 5.3 | |||

| 100 | 3.0 | 94.5 | 9.6 | 9.0 | 3.5 | 53.70 | 96.5 | 3.15 | 1.75 | 5.3 | |||